Control cabinets for special requirements from Vienna

Perfectly looked after from planning to commissioning!

Individual solutions are our strength! compact electric manufactures control cabinets according to customer requirements for heating, ventilation and air-conditioning technology as well as system control.

Our control cabinets are used in the following areas:

- Building services

- Sewage and water management

- Industrial plants

- Power distribution systems

- Tunnel fan control centres

Control cabinet construction with a comprehensive service

Your specific requirements are the focus of the project. Therefore, the planning of the control cabinet is carried out in close cooperation with you, because every company has different requirements. With us, you can take the promise "All services from one source" literally, because: Our range of services includes complete project planning of the detailed design, production of the cabinet, connection and commissioning on-site – including service. We produce every cabinet according to exact quality specifications, which are defined throughout the company within the framework of ISO 9001 certification.

Team and reference projects

A total of 30 employees work in production and ensure the perfect quality and function of the enclosure. In case of capacity bottlenecks, the staff is reinforced by additional skilled workers. In this way, we are properly staffed for every order.

Our references include many major projects such as the museums in Vienna, the Olympic Village in Athens, the hospital in Steyr and the hospital in Mistelbach.

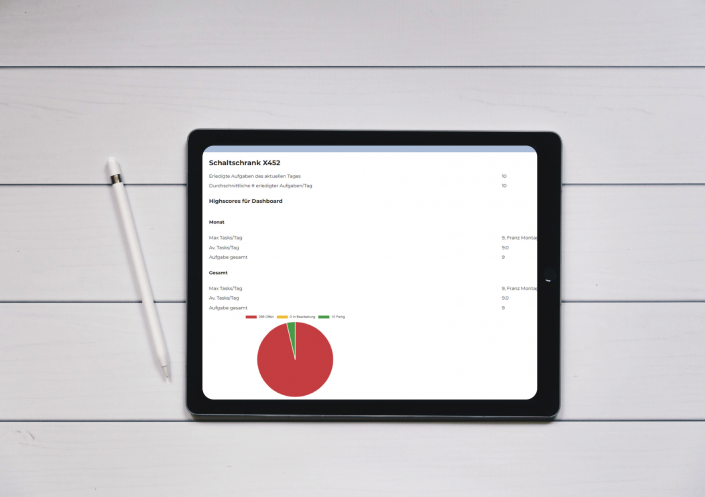

Working software for control cabinet technology

Make the most of all the advantages our control cabinets offer – with the working software for control cabinet connections with real-time documentation. PLUGIN 4.0 is the ideal tool for defining, planning and evaluating projects for use on the construction site, for support during work and data acquisition and documentation.

PLUGIN 4.0 offers the following benefits in technical terms:

- Significantly more efficient work instructions and faster implementation of work.

- Automated traceability of activities

- Duplication of processes is prevented

- Logging of activities

- Simplified accounting processes

- Local conditions are better managed

- A flexible, gender-oriented organisational system

- Significantly more economical and transparent construction site activities

- Opening of the labour market

On the dashboard, statistics and work steps are displayed on a project-by-project basis. These include, in particular, the number of completed tasks for the current day.

Would you like to learn more? Then send an e-mail to:

Ing. Thomas Plasser (authorised signatory)

Managing Director Mag.a Ulrike Haslauer